SOLVING PRODUCT DATA HEADACHES

Product Information Management (PIM) | Business Process Improvement | PIM software

Fixing Poor Data Quality

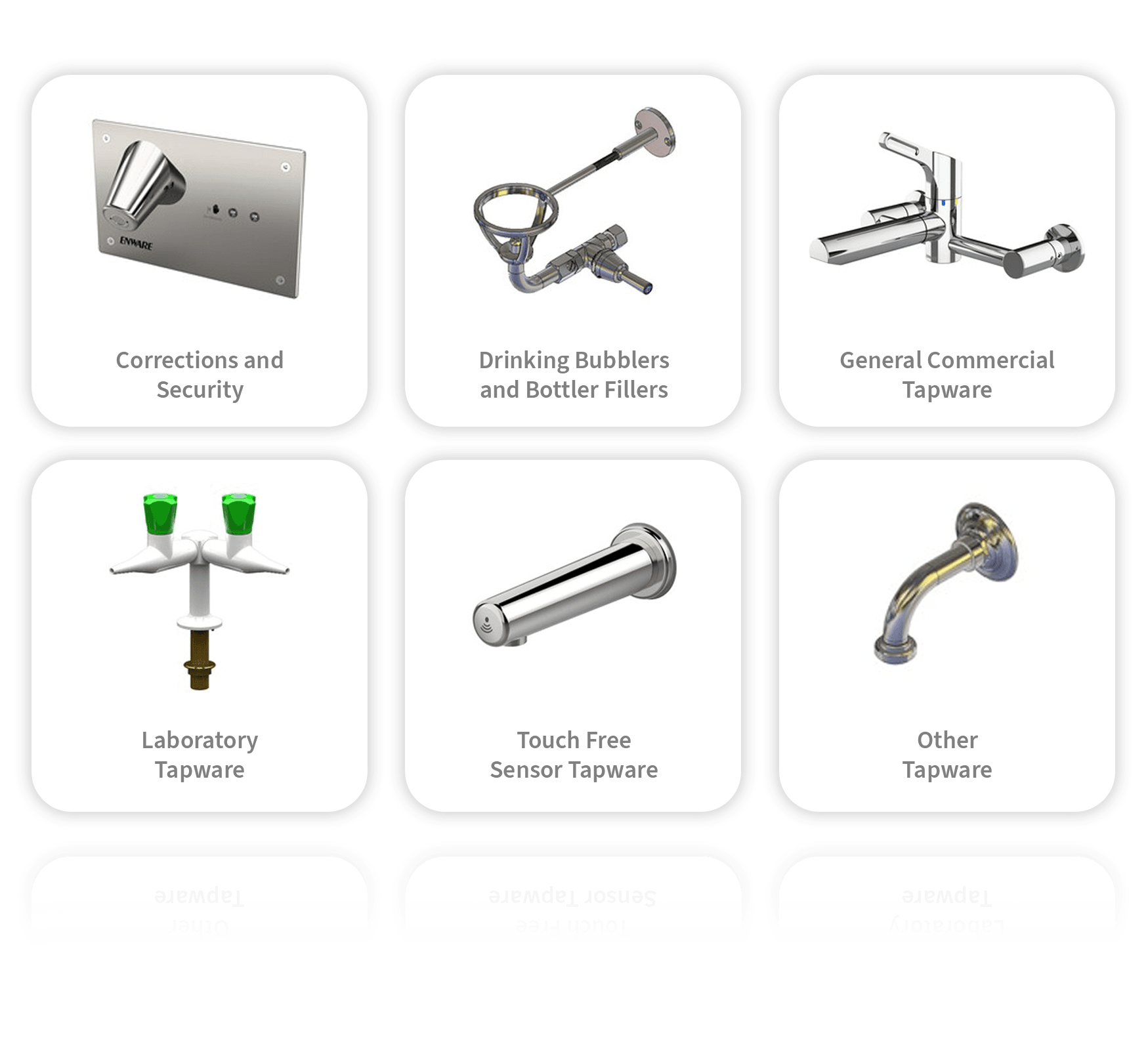

Enware, based in Sydney, is a manufacturer and supplier of specialist plumbing and safety equipment to a wide variety of commercial industries. They have design, engineering and wholesaling capabilities, and over 5,000 SKUs (products).

Enware's product data was spread across multiple systems and formats, with no definitive version of the truth. To access reliable information about each product, the Enware team relied heavily on internal subject matter experts (SME). The SMEs were leaned on frequently to answer a lot of questions, often causing delays in responding to customers and preventing the SMEs from undertaking their assigned work.

One of Enware’s biggest problems was not knowing how poor the quality of their data was. There was a lack of transparency beforehand, data was across multiple sources, and critical information was often missing, nor captured in a central location when provided by an SME. The missing information made it difficult to effectively market and sell products, or service customers pre- and post-sale.

Enware recognised the need for a systematic approach to the management of product data with the ability to wholistically view the data and address what needed rectifying.

Sales Layer PIM Software

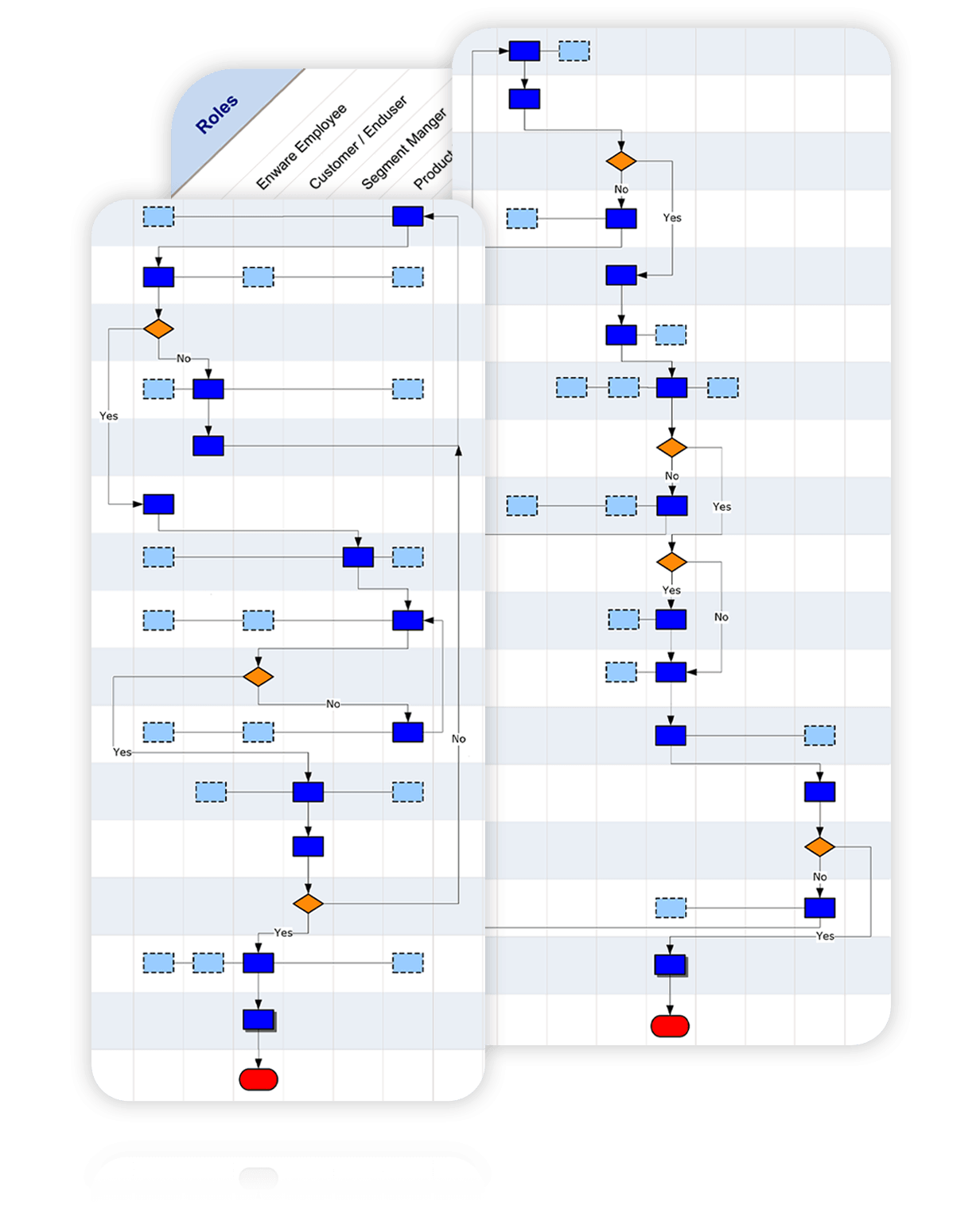

Ascend 7 proposed solving these challenges by focusing on a People, Process and Technology solution, and by implementing a Product Information Management (PIM) system and improving associated business processes. The solution aimed to improve the processes around how product information was created, used and maintained at Enware as well as implementing the Sales Layer PIM as the one definitive source of truth for ALL Enware product data.

The Sales Layer PIM software has the most user-friendly and easy-to-learn interface, and offers the best support and customer service. It is extremely agile for creating customised product experiences, with workflows to improve product data collaboration between dispersed teams and departments.

What Enware liked most about Sales Layer was the:

flexibility of the fields and tailoring it to Enware's specific needs whilst still maintaining consistency

bulk loading of information, after identifying data gaps

different views with different functionality - thumbnails, list and table view – were useful for different roles and users

reporting, to let Enware understand what data needed to be populated, based on quality ratings and the ‘field’ view under reporting

being able to see what had been changed and by who - visibility of all editors and what they have edited increased accountability, and kept it all transparent

magic wand feature for descriptions - effective for generating product descriptions, which often just needed tweaking.

"Game-Changer" Outcome

Introducing the Sales Layer PIM has been a game changer for the Enware business. Employees can now cross reference products, spare parts, part numbers, part IDs and sales codes with ease, which in turn, increases confidence in the information, saves time and effort and facilitates better and faster servicing of customer needs. Enware is also less reliant on their SMEs, removing them as a bottleneck in common business processes and allowing them to undertake their assigned roles.

Sales Layer has formalised and streamlined Enware’s product lifecycle processes which has reduced the occurrence of re-work and duplication of effort, prevented product status black holes, improved confidence in the product information accessed, negated the need for local storage, and significantly reduced product information errors. Employees are now able to generate collateral and assets automatically from the Sales Layer data, which is a huge time-saver. All the information being in one place means everyone across the business can access it and know it is accurate.

Overall, the introduction of Sales Layer has improved confidence in product information which has resulted in better product decisions, increased sales and improved customer service.

“Ascend 7 were really easy to work with. They were skilled in liaising and dealing with challenges around complex processes while always having the big picture in mind. They used simple processes to make it easy for our team, which got Enware to the end destination with small bite-size pieces of work. Ascend 7 is the first technical partner, who I’ve personally worked with, that has under-promised and over-delivered. And we would absolutely recommend Sales Layer as a PIM solution to other businesses like ours.”

Avril-Summer Cusack

Marketing and Communications Manager, Enware

“Ascend 7 took the time to understand the needs of our business right from the start. This information was the core guidance to evolve the Sales Layer PIM software into a unified system that is now how our whole business manages product information. The Ascend 7 team were there at every stage helping and guiding where needed to ensure the PIM project was on time and achieved the best possible outcome for our business.”

Matthew Luks

IT Coordinator, Enware